Bearings are one of the most critical equipment in a rolling mill and they perform three basic functions carrying a load reducing friction and positioning moving machine parts rolling mill.

Bearings are required to withstand extremely severe operating conditions including heavy shock loads bearing speeds and extreme temperature variations. In most of the cases, the bearing has to withstand both the radial roll separating force and the rolling thrust as illustrated in here.

Traditionally many types of bearings are used in a rolling mill of which fibre or fabric bearing is the most commonly used one. There are many bearing suppliers in India who can provide you bearings according to your specification and requirements.

A fabric bearing is composed of a fabric such as cotton impregnated with a raisin and is manufactured by moulding or wrapping according to the type of resin used.

Suggested article: What is bushing?

Consequently, they take the form of shell bearings which are fitted into jobs. A fabric bearing is subjected to a linear contact with the rotating rolls thus these bearings lead to more friction thereby leading to significant mechanical losses and comparatively higher power consumption.

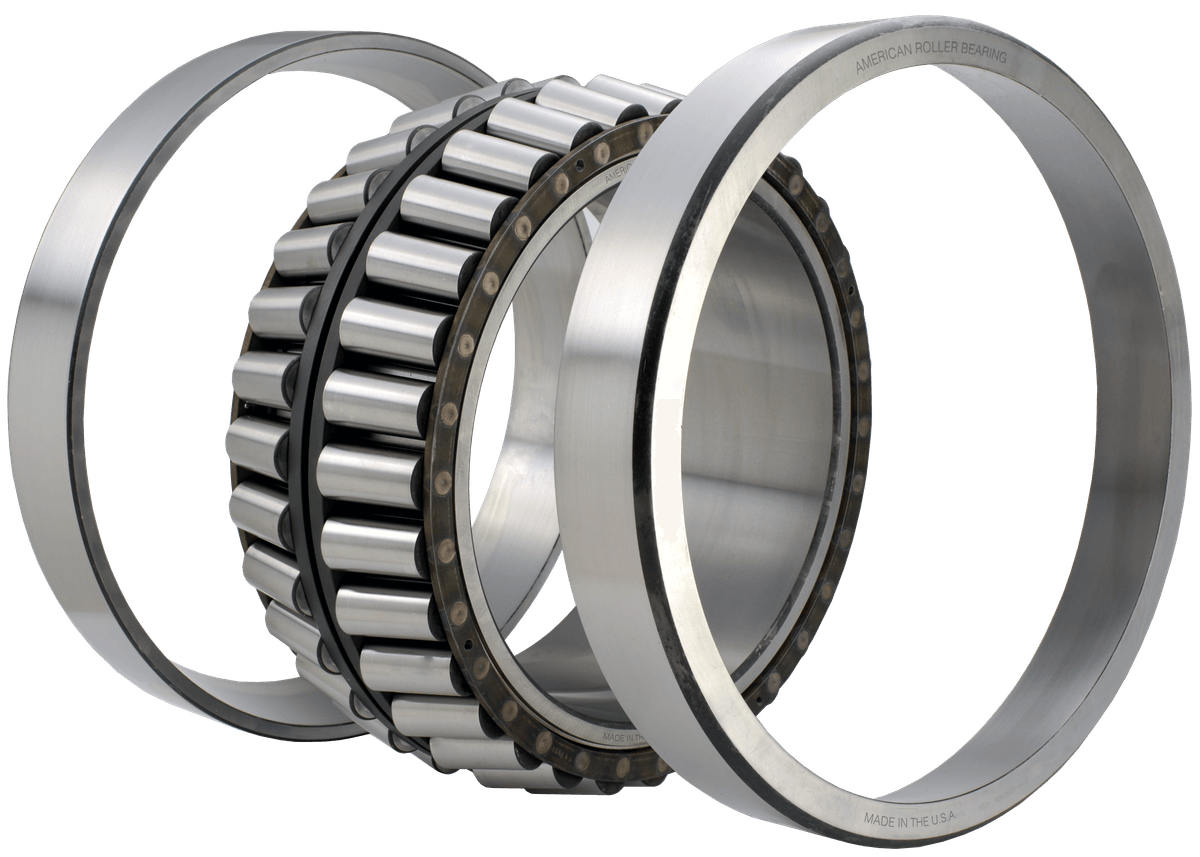

An alternative to the fabric bearing is an anti-friction roller bearing. A typical roller bearing consists of an inner ring and outer ring rolling elements and a retainer in a typical installation the outer ring is fixed and doesn't move. As the shaft rotates the inner ring also rotates the retainer positions the rollers equally along with the Rings and ensures that the load is distributed equally on each roller.

The advantages of roller bearings are rollers are subjected to point contact as compared to line contact in fabric bearing coefficient of friction for rollers is 0.005 compared to 0.54 fabric leading to less friction and heat.

Rollers are subjected to less starting and running torque compared to fabric bearing leading to less power consumption.

The hardness of steel bearing is far better than fabric bearing leading to longer life roller bearing improves mill availability to suit different types of rolling profiles different types of bearings are available.

The spherical bearing is preferred for ball mill flat rolling and light sectional mill. Tapper bearings are preferred for flat rolling light and heavy sectional mills. Cylindrical bearings are preferred for flat rolling and heavy sectional mills. To better understand the benefits in terms of economics let's take the example of a 10 DPH rolling mill.

The rolling mill consists of 10 stands equipped with fabric bearing. Let's consider the conversion of 8 stands from fabric to roller bearing. The changeover from fabric to roller bearing would mean an investment of 20 lakh rupees the changeover will lead to a saving in specific power consumption by 7% annual power saved for the 10 tbh plant would be around 2.2 lakh units of electricity or 220,000 500 kilowatt hours which implies 15 points 5 lakh rupees cost-saving annually.

Thus the investment can be recovered in close to 15 months other benefits achieved are longer bearing life lesser breakdown more hot ass and improved. Miller fishin see we need to make sure that housing stands have enough space for placing bearings the size of the roller and bearing should be checked before fitting the bearings and it should be lubricated periodically.

Related articles: